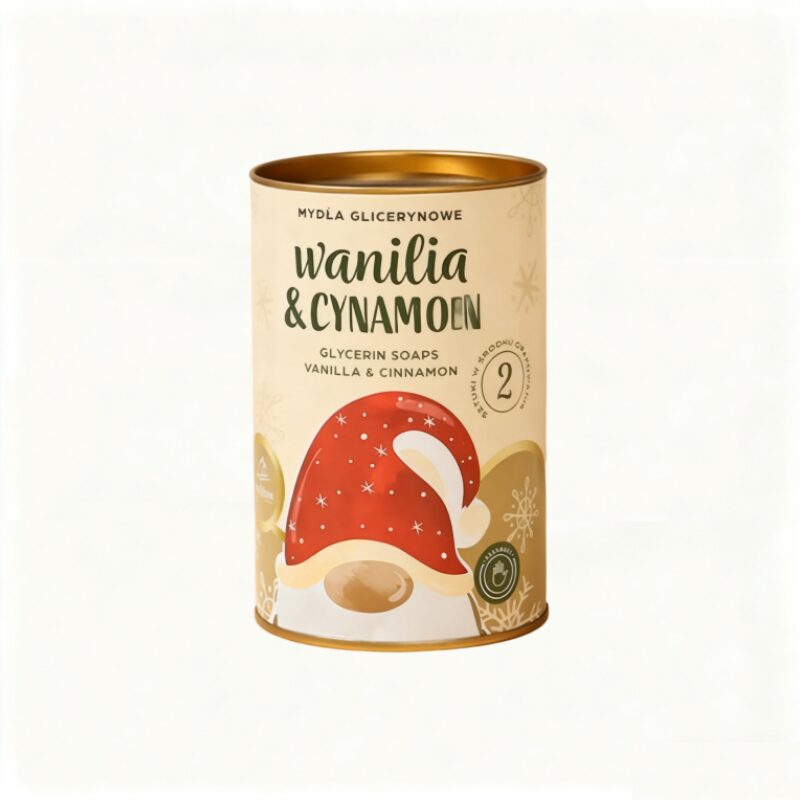

They are generally categorized into three basic types, and are used across various retail applications, including cosmetics, personal care, cannabis, CBD products, electronics, household items, and food packaging.

Custom Paper Tubes for Demanding Applications

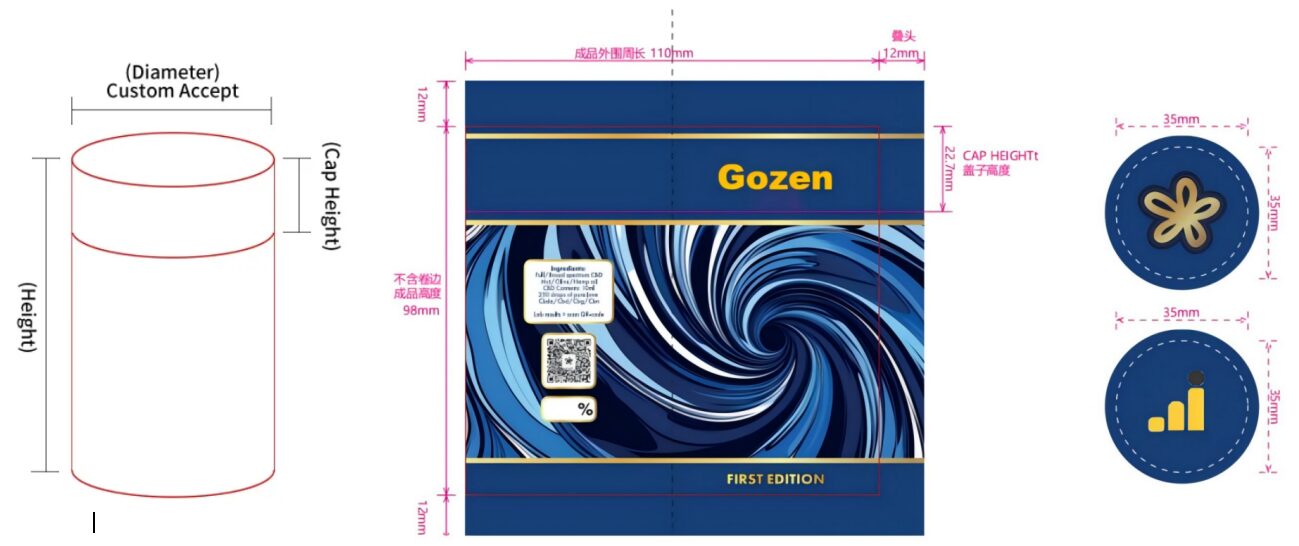

We produce precision-engineered paper tubes and cores tailored to your exact needs. Available in diameters from 6mm to 628mm, lengths from 15mm to 6,500mm, and wall thicknesses from 0.6mm to 15mm, we deliver both versatility and reliability.

Customize with printing for branding or specifications on inner or outer surfaces, and choose from specialized finishes: colored, embossed, UV spot, silicone-coated, PE-layered, hydrophobic-coated or adhesive-ready.

We offer tubes in unique, eco-friendly solution that provides superior protection for posters, documents, cosmetics, CBD products, and luxury goods, securing goods during transport; or even decorative uses.

With full-color printing, you can showcase your logo and design directly onto the tube, turning simple packaging into a powerful marketing tool.

We combine exacting quality standards with adaptable processes to create high-strength, application-specific solutions. Get in touch to request samples or discuss your project requirements.

Our Benefits

Order Online

Prices and Response available 24/7

Small Minimums

200 units to start a order

Rotogravure Printing

Pantone spot colors

Digital Printing

HP indigo CMYK colors

Quick Turnkey

Super fast turnaround

DDP shipping

Door to door tax and duty included shipping.Free from tax and tariff worries

FDA and CE Certified

BPA free and heavy metal free

One-stop supply chain

Get access to our optimized supply chain to source any packaging products, boxes, sleeves, tubes, etc.

Clients oriented

Aim to provide suitable solutions for per each client case

High quality yet competitive

No compromise on quality and prices, you can have both here

Custom Paper Tubes by Styles

Piece Paper Tube

Also called a single paper tube, it’s a machine-wound, cylindrical container made from one continuous piece of paper or cardboard.

Piece Paper Tube

It features a two-part construction: a top cap and a base that can slide into each other.

Piece Paper Tube

Also known as butt-jointed tubes or flush-fit cardboard containers, it includes a base, collar, and lid.

Child Resistant Paper Tube

Featuring an innovative two-step opening mechanism, these child-proof tubes combine safety with a sleek design that enhances brand recognition.

Bottom Push-Up Paper Tube

With a movable bottom disk, it can push contents upward for easy access. Ideal for lip balms, deodorants, and other solid/semi-solid items.

Display Window Tube

These tubes with window cutouts offer a perfect way to visually showcase products inside while still sealed.

Custom Shaker Tube

They are designed with a perforated or slotted top for controlled dispensing. Ideal for powders, spices, and cosmetics.

Membrane Lid Tubes

These tubes are sealed with a thin, protective membrane that ensures product integrity and prevents leaks.

Rectangle Tube Box

Featuring a unique rectangular cross-section, these tubes offer a modern and stable design.

Oval Shape Tube

Designed with an oval shape, they offer an elegant and user-friendly experience.

Why Choose Our Tube Packaging?

- Strong & Protective: Made from sturdy cardboard and kraft paper,ensuring your products stay protected during storage and transit.

- Fully Customizable: Choose from luxury tubes, custom mailing tubes, or cosmetic tubes- including printing, finishes, and functional features—all tailored to your brand.

- EcoLooking: Our recyclable kraft paper and paper tubes help you support the environment.

- Cost-effective:Premium packaging that fits your budget, whether you’re a startup or a mature

- Free Expert Help: Take advantage of our free consultation service and 1:1 professional design solutions for a worry-free experience.

- Dedicated Customer Support: Our team is available 24/7 to answer your questions and provide swift, solutions-oriented support.

Let us help you create packaging that’s right for you.

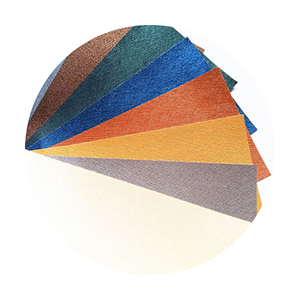

Paper Material Types

From natural Kraft to luxury Metallic Paper – explore 12+ specialized materials engineered for exceptional paper bags.

Each FDA-compliant material combines functionality with brand personality.

black card

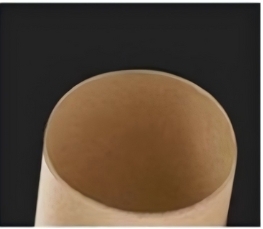

brown kraft

coated paper

color dyed paper

corrugated paper

embossed paper

brown kraft

coated paper

color dyed paper

white kraft

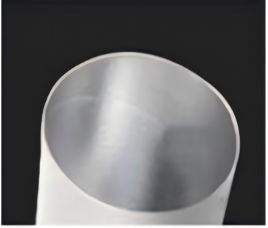

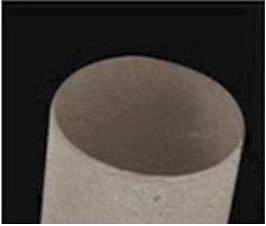

Inner Liner Materials

Food grade

Kraft

Aluminum Foil

White Card

PE Laminated Film

Non - Food grade

Bobbin Paper

Grey Board

Kraft Liner Paper

Writing Paper

Extra Add-ons

Lamination process

UV

Stamping

Laser effect

Debossing

Embossing

Color Printing

Writing Paper

Our paper tube packaging is crafted through a precise, multi-step process:

1.Winding

Layers of paper or cardboard are spiral-wound around a mold and bonded with adhesive to form a sturdy tube. The thickness, strength, and diameter can be customized based on material and number of layers.

2.Precision Cutting

The tube is cut to the desired height or length manually or automatically.

3.Printing & Labeling

Printed artwork or branded outer wrap is applied to transform the plain tube into personalized packaging.

4.Second Cutting & Curling

For multi-piece sets, the printed tube is cut again into sections (like a cap and base). The edges are often curled for a finished look, and end closures are added.

5.Inserting Inner Components

Finally, add the internal parts, such as an inner neck, which is securely glued into the outer base section to complete the assembly.

This is a glimpse into making a standard three-piece tube. As a specialist manufacturer, we also offer one-piece and two-piece structures, providing the perfect packaging solution — tailored to your specific needs and budgets.

Get Quote

CMYK Offset Printing

Digital Printing

Flexography

Rotogravure

Environmental Sustainable Paper Tube

Paper tube packaging stands as an innovative and eco-friendly solution, designed with sustainability at its core. They’re crafted from recyclable and biodegradable materials like FSC certified paper, water or bio-based inks.

We know that the definitions of “recyclable” and “compostable” vary by region based on local policies and capabilities.

Our team provides targeted solutions to ensure compliance in your specific market. Such as solutions include materials with <5% plastic , <15% metallization, or fully recyclable high-barrier properties.

Get QuoteCustom Your Paper Tubes

We don't just supply paper tubes; we craft vessels for your brand's story. Choose the exact specifications: inner diameter, height, volume, and color. Then, make it uniquely yours with a full-color print of your logo, design, or brand artwork.

Certifications

FSC Certified

Paper materials used are sourced from forests that are managed responsibly.

OK Compost Home

Certifies material is compostable in a home compost

OK Compost Industrial

Certifies a material is compostable in industrial compost facilities

Global Recycled Standard (GRS)

Certifies products obtained from recycled materials and manufacturing activities

Custom Printed Paper Boxes Orders Shipment Records

Case Sharing

Paper Tubes FAQS

-+What material are the custom boxes made from?

Our custom boxes are made from a variety of high-quality materials to suit different needs. Here are the main types we use:

Corrugated Cardboard: This is the most common material for boxes and cartons. Its layered structure (liner, medium, and fluting) offers durability and strength. Choose the specific type based on the weight and features of your product.

White Cardstock: A stiff, smooth paper, perfect for retail and card boxes. We commonly use 250 GSM, 300 GSM, 350 GSM, or 400 GSM white cardboard.

Kraft Paper: Known for its toughness and water resistance, this material offers high tear and burst strength, usually brown or white in color. We often use 190GSM or 250GSM in either brown or white.

Art Paper (Double-Sided Coated Paper): Has a glossy, bright white surface on both sides. It’s excellent for high-quality color printing on both sides, ideal for high-end gift boxes.

Grey Board Paper: An extra sturdy and rigid board, ideal for luxury and high-end gift boxes. It offers greater durability and better flexibility compared to regular cardstock.

Whether you need practical protection or premium presentation, we have the right material for your product.

-+Can I have a custom designed and made packaging box?

Yes, absolutely. Gozen Box custom designs each project to our clients’ exact specifications, creating boxes and bags based on the provided crafts and packaging needs – we specialize in customizing boxes to the exact dimensions (L x W x H) of your product’s size for a perfect fit.

-+Can I review a proof or a sample before your full printing of the order?

Yes. Since presentation is key for packaging, we’ll provide a free digital proof for your approval before we begin any production. We’ll only move forward once you’re 100% happy with it.

Proofing typically utilizes digital printers. Due to differences in equipment and process compared to mass production, proofs may have slight variations in texture, appearance, thickness, and color from the final bulk order.

Proofs are for reference only and are not the standard for approving mass production.

For dimensional verification, a physical proof is recommended. If the purpose is to evaluate printing techniques (special finishes excluded), we advise a small batch order, as proofs cannot fully replicate mass production outcomes due to variations in machinery and process.

Offsetting sample costs against bulk order payments requires meeting the following conditions:

- Confirmation: Please confirm with our sales staff if your product is eligible.This depends on the specific product box type, processes, and other factors.

- Consistency: The specifications, materials, and technical requirements of the proof must exactly match those of the mass printing order.

- Payment: The samplefee must be paid upfront before production begins.

-+What if I don't have a design ready for print?

The Gozen expert team can provide 1:1 design service solutions for a worry-free experience. We input much time and labor in the artwork as well as proofreading communication. In the talk, our sincerity and expertise, professional ideas, timely response can be seen and felt directly.

-+What format should my design be in?

To ensure the highest quality, we recommend providing your artwork in vector formats such as CDR, AI, PDE, or EPS, with colors set to CMYK mode. If these formats are unavailable, high-resolution (300 DPI or higher) raster images like JPG or TIF are also acceptable.

Please note that files created in office software (e.g., Word, Excel, PPT) do not meet professional printing standards.

Email: Info@gozenpackaging.com

Email: Info@gozenpackaging.com Wechat: +86 18571566509

Wechat: +86 18571566509 WhatsApp: +86 18571566509

WhatsApp: +86 18571566509 Office: +86 27 85817670

Office: +86 27 85817670