Why Flexible Packaging is the Future?

Why We Need Packaging?

Packaging is the first thing that catches customer’s attention. Whether a product is purchased online or in-store, the packaging is the first thing the customer sees. And this will have a long-lasting effect on their view of the product and the brand.

In recent years, packaging has become increasingly important as people share “gift unboxing” and “unboxing” moments on social media. This rising trend shows that branded packaging can be a powerful marketing tool.

To create a positive first impression and foster long-term brand loyalty, product packaging is a factor that manufacturers cannot ignore. The six reasons of why we need packaging have come to Gozen as a result of years of experience.

Protection: At its most base level, product packaging serves to protect the contents from any damage during transport, handling and storage. It protects the product from humidity, light, heat and other external factors.

Safety: The packaging should contain important information about the product and its safety. For example, packaging date, ingredient list, whether it contains toxic substances, etc. All the information enhances the safety of the product for consumers.

Attracts buyers: Unique packaging can add to the appeal of a product and thus influence people’s willingness to buy it. Choose styles colours and high-quality packaging materials that will attract consumers and encourage them to buy the product.

Usability: Consumers are looking for fit-for-purpose packaging. They want packaging that is functional: easy-open, easy-fold and sort, or can be reused. Optimal design enhances usability.

Differentiates from competitors: The choice of packaging colours, fonts and styles can make your products stand out. Innovative designs like shaped bags, and clear plastic boxes will set your product apart.

Sustainability: More consumers are evaluating the carbon footprint and recyclability of packaging before purchasing. Using eco-friendly materials (kraft paper, PLA, LDPE, PCR) can improve brand image and consumer trust.

What Is Flexible Packaging?

Flexible packaging is often shortened to flexpack. It includes any kind of packaging made of flexible materials (plastic, paper, film, foil, etc.) as opposed to packaging made of rigid materials (such as cardboard, glass or molded plastic).

A familiar contrasting example: biscuits packaged in cardboard boxes (rigid packaging) and biscuits wrapped in clear plastic (flexible packaging). Each material in flexpack has its unique function in protecting or enhancing the appeal of different packages.

As its name suggests, flexible packaging is a versatile and adaptable solution that can be easily moulded, folded or re-shaped.

It adapts to the shape of the product while providing protection and convenience. Ideal for resisting moisture, mildew and other environmental factors, flexible packaging effectively protects products from damage.

Its benefits include being lightweight, cost-effective, reducing carbon footprint, extending shelf life, and allowing unlimited customization. These factors make it a top choice for businesses.

Primary Types Of Flexible Packaging

Flexible packaging comes in a variety of materials, shapes and sizes and is often produced in either formed or unformed form. The materials used in flexible packaging are easy to handle and can be combined into innovative and customizable styles, such as:

Stand-up pouches, a staple of flexible packaging, have revolutionized the packaging landscape.

Their self-standing design allows them to stand on the shelves to catch people’s attention.

They provide ample space for branding and product information.

From snacks, coffee, pet food and lifestyle products(such as cannabis), stand-up pouches are the ideal packaging option.

Flat-lay bags are a flexible and versatile packaging option.

These bags lay flat when empty, greatly facilitating storage and transport.

Its compact design effectively reduces material waste, making it a sustainable packaging solution.

Particularly suitable for products such as spices, powders and single-serve foods.

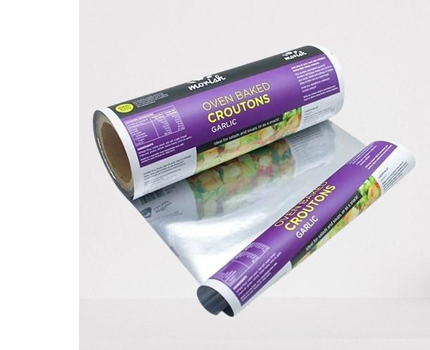

Printed roll stock consists of pouch material before it’s converted to a pouch.

A continuous roll of printed film with barrier and structure films already laminated to it.

These rolls get sent to a co-packer to get formed, filled, and sealed.

It works well with different packaging machines, making it a convenient choice for large-scale production.

Sample Pouches:

Sample pouches are small packages of film and/or aluminium foil that can be heat-sealed.

They are usually pre-formed for easy internal filling and sealing.

Sachets:

Sachets are flat packets made of layered packaging material.

They are frequently used for single-use pharmaceutical and personal care products.

Vented Sealed Produce Bags:

They are another innovative flexible packaging solution.

These clear plastic pouches are ideal for storing and displaying fruits like grapes and tomatoes.

The vent holes provide excellent ventilation, keeping produce fresh and visually appealing.

These bags also feature a tear-resistant design with a folded bottom for stability.

Primary Films Of Flexible Packaging |

| 1. Low-density Polythene (LDPE): | 2. Linear Low-density Polyethylene (LLDPE): |

| Low-density polyethylene is an extremely flexible, lightweight plastic material.

These films are known for their low-temperature flexibility, durability, corrosion resistance, chemical resistance and impact resistance. They are quite easy to fabricate by using a high-pressure process. |

This material is great at absorbing impacts and is less likely to puncture or tear.

It is basically an evolved form of LDPE. In addition to their flexibility, these films are renowned for their durability and resistance to chemicals. |

| 3. Biaxially Oriented Polypropylene (BOPP): | 4. Biaxially Oriented Polyethylene (BOPE): |

| These films exhibit unquestionable durability, high tensile strength, resistance to moisture, and excellent transparency, making them highly suitable for retail packaging. | BOPE is the ideal solution for packaging products that require high stiffness.

The best features of these films are good puncture resistance, excellent heat-seal strength, durability, and moisture resistance. |

| 5. Biaxially Oriented Polyethylene Terephthalate (BOPET): | 6. Biaxially Oriented Polyamide (BOPA): |

| These are made from stretched polyethylene terephthalate (PET).

They are popular for their transparency, reflectivity, high tensile strength, chemical stability, gas and oil barrier properties, and electrical insulation. |

Similar to BOPET, BOPA is also known for its excellent tensile strength, durability, aroma barrier properties, and puncture resistance.

However, its most prized feature is its high degree of transparency. It’s also an awesome barrier against oxygen and certain chemicals. |

| 7. Ethylene-Vinyl Alcohol (EVOH): | 8. Laminates: |

| EVOH is very common in food packaging, known for its excellent barrier resistance to gases like oxygen, nitrogen, and carbon dioxide.

It also has great flex-crack resistance and is resistant to hydrocarbons, oils, and organic solvents. |

Laminates usually comprise a multi-layer structure, with one of the polymer films or paper supporting the aluminum or metalized films.

They are also designed to provide an excellent odor or aroma barrier. |

Why Flexible Packaging Is The Future?

Flexible packaging is gradually becoming the preferred choice of the packaging industry. In addition to being a straightforward form of packaging, it is poised to become the future leader of the packaging industry. Its development potential is set to drive the entire market to new heights.

Convenience and Portability

Flexible packaging materials are designed to be lightweight. It provides benefits such as ease of storage, easy opening and resealing, and convenient on-the-go use. Compared to glass containers or rigid plastic packaging, lightweight flexible packaging is perfect for busy lifestyles. Additionally, flexible packaging is extremely durable and it offers versatility between single-serving and multi-serving packages.

Extended Shelf Life

With high-barrier films and airtight seals, flexible packaging helps to protect highly perishable products from oxygen and moisture. This keeps products fresher for longer. The resealing technology of flexible packaging also guarantees that food products remain fresh after multiple uses. All of this helps to reduce food waste, which in turn helps the environment.

Design Flexibility

Flexible packaging offers impressive design versatility. It can be branded in 360 degrees with high-quality, high-impact graphics that provide a bright, clear design. All of which contribute to an enhanced brand image and capture consumer attention.

Simplified Shipping and Display

Flexible packaging, like flat bottom bags or three side seal pouches, takes up less space than glass bottles, jars or boxes. You can put more products on the shelf at once, and the display of each product can be flexibly selected. Besides their lightweight design, you can ship more products at once. The reduction in weight and space means that transport costs will be reduced much.

Quick Turnaround

With digital printing on flexible packaging, you can get all your short or long runs in a matter of days rather than weeks. So you can get your product to market quickly. This helps you avoid problems with inventory space and cost. You also will have faster set-up, and flexibility to make changes to the design quickly.

Environmental Benefits

Flexible packaging is responding to sustainability by offering eco-friendly options, such as biodegradable and recyclable materials. This shift is beneficial for the environment and aligns with the growing consumer demand for sustainable products.

Elevate Your Packaging Experience with Gozen

Flexible packaging offers a variety of benefits, including versatility, product protection, convenience and sustainability.

In the dynamic consumer goods sector, Gozenpackaging has extensive experience in providing high-quality digitally printed flexible packaging solutions. We offer fast delivery times, low MOQ, and a wide range of customization options to meet customers’ specific needs.

With our printing technology and professional solutions, customers can easily create personalized packaging to suit individual preferences. If you would like to discuss how we can transform and elevate your packaging experience, please get in touch.

Email: Info@gozenpackaging.com

Email: Info@gozenpackaging.com Wechat: +86 18571566509

Wechat: +86 18571566509 WhatsApp: +86 18571566509

WhatsApp: +86 18571566509 Office: +86 27 85817670

Office: +86 27 85817670